Technical

Technical

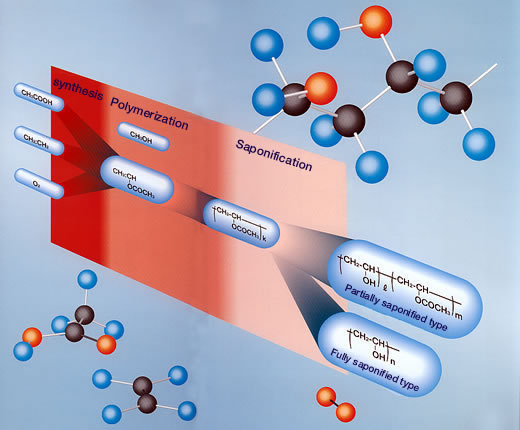

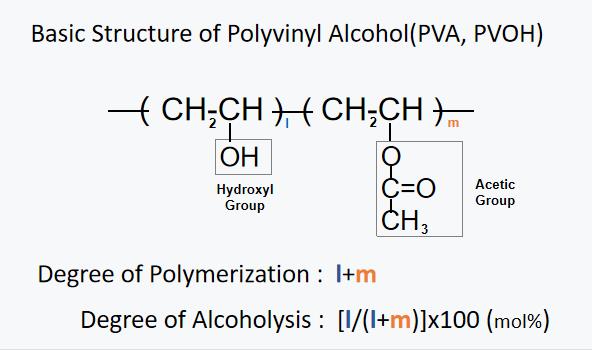

Joyforce PVOH products can be roughly categorized into two types; a fully saponified type comprising mostly hydroxyl groups, and a partially saponified type retaining a certain portion of acetic groups. The relation between the fully saponified type and partially saponified type can be illustrated as below.

Dissolution

Precautions for Dissolution: Adding a large quantity of PVA at once may create undissolved lumps. Make it sure to use room temperature water and add PVA little by little under agitation. Additionally, be careful to raise the temperature of the solution after checking the dispersal of PVA particles.

By dissolving PVA in water, transparent and viscous aqueous solutions are obtained. Dissolution temperature changes according to the alcoholysis value. A typical dissolution method is shown below.

1. Pour PVA into room-temperature water little by little under agitation so that it disperses in the water.

2. Heat the solution under continued agitation. Keep the temperature between 80 and 90℃ under agitation for 30 – 60 minutes until complete dissolution.

3. Be sure to avoid rapid temperature increase, as this causes drastic foaming.

Operation Tips

Storage

The product should be stored indoors where is dry and well ventilated and stored separately based on the lot numbers. The room temperature will be better between 5-30℃. Keep away from heat resources, moisture and exposure of sunshine. Storing together with volatile chemicals should be strictly prohibited so as to avoid exchanges of the characteristics from absorption.

Anti-Foaming

Foaming may cause a problem when PVA is dissolved or a PVA solution is used. The degree of foaming varies depending on the grade of PVA, the concentration and temperature of the solution, or other operating conditions. The addition of an anti-foaming agent such as an alcohol-based solvent, commercially available silicone emulsion, or polyethylene oxide-poly propylene oxide (PEO-PPO) block copolymer is effective.

Gelation

Boric acid and borax are typical gelatinizing agents for PVA aqueous solution. It is required a smaller amount of borax compared with boric acid to make gelation of PVA solutions. Highly concentrated Fully Alcoholysis PVA solutions will gel if the solutions store in low temperature.

Plasticizing

If flexibility is required, adding an appropriate amount of polyhydric alcohol such as ethylene glycol or glycerin as a plasticizer to PVA is effective. When using a plasticizer, be sure to refer to the instruction manual of the plasticizer for handling information.